Lemken

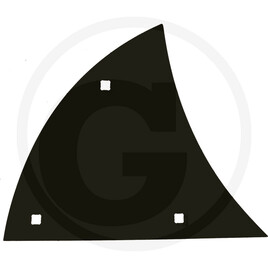

- Designation:

- B2K

- Version:

- B2K

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Designation:

- B2K

- Version:

- B2K

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

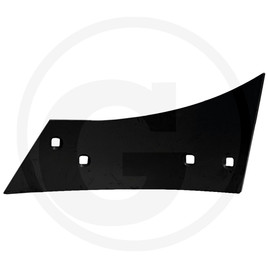

- Designation:

- BU2K

- Version:

- BU2K

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Designation:

- BU2K

- Version:

- BU2K

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

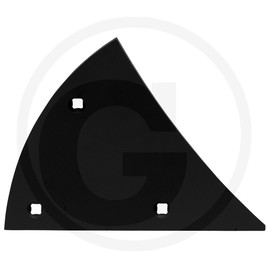

- Designation:

- C2K

- Version:

- C2K

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Designation:

- C2K

- Version:

- C2K

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

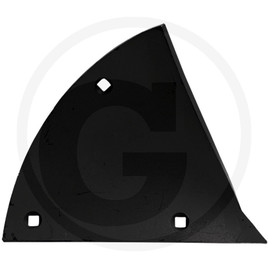

- Designation:

- B2KH

- Version:

- B2KH

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Designation:

- B2KH

- Version:

- B2KH

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Designation:

- BS40

- Version:

- BS40

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

Special item: cannot be returned or cancelled. Additional shipping costs may be incurred. Delivery time subject to availability from the supplier.

- Designation:

- BS40

- Version:

- BS40

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Designation:

- BS40

- Version:

- BS40

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Designation:

- BS40

- Version:

- BS40

- Assembly notes:

- Mouldboards and slats:

When changing mouldboards and slats, tighten all bolts to prevent stresses and cracks in the components. Use cardboard discs to compensate for mouldboard and mouldboard front part dimensional tolerances in order to prevent stresses and cracks in the components. Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

Original spare part numbers are for comparison purposes only. All prices are in $, excl. VAT. Errors reserved. Delivery subject to availability.