Oil service valves, metric

Oil service valves are designed for unpressurised oil draining.

Simple, safe handling and an optimum flow rate were the most important features when developing these oil service valves.

Other features include:

- High temperature resistance (-30 - +200°C)

- Low flow resistance

- 100% tested for leaks

Oil service valves are TÜV tested and DLG approved

Functionality:

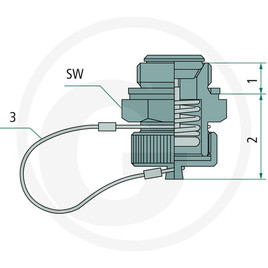

The illustration shows an oil service valve installed in a container or oil sump filled with a medium containing oil. After removing the protective cap supplied, a suitable connector is screwed onto the valve. As the connector is screwed on, the valve plate opens and the liquid flows unhindered into a waiting container. When the liquid has drained off completely, the connector is unscrewed again. The valve plate is lowered and the valve is tightly closed once again. The protective cap is now screwed on, fresh medium is poured in, and everything is ready.

Advantages:

- No risk of burns from hot oil

- No contamination of the machine or the environment

- No destruction of the oil sump thread

- No gasket change, oil change in any location

- Less time required

Simple, safe handling and an optimum flow rate were the most important features when developing these oil service valves.

Other features include:

- High temperature resistance (-30 - +200°C)

- Low flow resistance

- 100% tested for leaks

Oil service valves are TÜV tested and DLG approved

Functionality:

The illustration shows an oil service valve installed in a container or oil sump filled with a medium containing oil. After removing the protective cap supplied, a suitable connector is screwed onto the valve. As the connector is screwed on, the valve plate opens and the liquid flows unhindered into a waiting container. When the liquid has drained off completely, the connector is unscrewed again. The valve plate is lowered and the valve is tightly closed once again. The protective cap is now screwed on, fresh medium is poured in, and everything is ready.

Advantages:

- No risk of burns from hot oil

- No contamination of the machine or the environment

- No destruction of the oil sump thread

- No gasket change, oil change in any location

- Less time required

Part no.

Connection thread

Screw-in thread

Material

AF (mm)

Pack of

Price & availibility

Part no.

Connection thread

M22

Screw-in thread

M16 x 1,5

Material

Steel

AF (mm)

22

Pack of

Unit:piece

Pack of: 1

Pack of: 1

Part no.

Connection thread

M26

Screw-in thread

M18 x 1,5

Material

steel

AF (mm)

27

Pack of

Unit:piece

Pack of: 1

Pack of: 1

Part no.

Connection thread

M26

Screw-in thread

M20 x 1,5

Material

steel

AF (mm)

27

Pack of

Unit:piece

Pack of: 1

Pack of: 1

Part no.

Connection thread

M26

Screw-in thread

M22 x 1,5

Material

steel

AF (mm)

27

Pack of

Unit:piece

Pack of: 1

Pack of: 1

Part no.

Connection thread

M26

Screw-in thread

M24 x 1,5

Material

brass

AF (mm)

30

Pack of

Unit:piece

Pack of: 1

Pack of: 1

Part no.

Connection thread

M26

Screw-in thread

M26 x 1,5

Material

brass

AF (mm)

32

Pack of

Unit:piece

Pack of: 1

Pack of: 1

OEM numbers are provided for reference purposes only. GRANIT replacement parts are not intended to be sold as OEM parts. Wilhelm Fricke SE is the manufacturer of all own brand items. All prices are in $, excl. VAT. Errors reserved. Delivery subject to availability.