GRANIT Chisel share

Coated

Part no.: 180180114

Further information

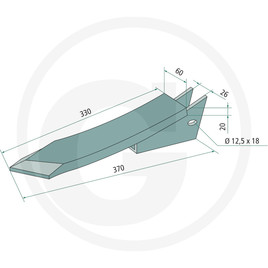

- Dimensions (mm):

- 330 x 60 x 20

- Thickness (mm):

- 20

- No. of holes:

- 1

- Working width (mm):

- 60

- Length (mm):

- 370

- Material:

- Description of the advantages of chrome carbide coatings

A special wear-resistant alloy is used to coat our GRANIT items. The carrier material used is an alloy with a high chromium content, to which tungsten carbide particles have been added.

The coating process takes place at extremely high temperatures in a controlled atmosphere.

The almost perfect cohesion between the coating and the body ensures maximum resistance and durability.

The coating is characterised by its compactness and its homogeneous surface.

The average hardness is around 600 HV with a carbide hardness between 2500 and 3000 HV.

The coating process used ensures excellent anchoring of the coating to the body.

Complete or partial detachment of the coating is almost impossible, even as a result of impacts caused by stones in the ground. The coating not only extends the service life of the tool, but also ensures high dimensional stability as a result of the low wear, which is essential for a consistently good work result. - Suitable bolts:

- 485931 12x045 08V

- Assembly notes:

- Do not tighten bolts and nuts with a compressed air tool as this may damage the wearing part (stress cracks).

- Verstärkungsvariante:

- Tauchbeschichtung

- Manufacturer:

- Wilhelm Fricke SE, Zum Kreuzkamp 7, 27404 Heeslingen, Deutschland, www.granit-parts.com, [email protected]

- Weight:

- 3,27 kg

- Catalogue:

- Tillage & seeding technology (p. 893)

- To be found in category:

- Tillage & seeding technologyGRANIT subsoilersEvers

Coated